Duct-O-Wire

The Problem:

Duct-O-Wire is the leader in electrification and control products for overhead cranes, monorails, hoists, trolleys, automatic stacker-retrieval systems and material handling applications requiring safe and economical moving power solutions. Duct-O-Wire partners with Jifram Extrusions, Inc. for an extrusion solution that meets quality and tolerances which are 100% to its specs. Duct-O-Wire has also called on Jifram’s engineering services for innovative solutions and enhancements for their OEM products. Jifram manufactures 23’ extrusions for the control units. Logistically these long channels presented a shipping challenge. To ensure the safety of the bulky extruded channels, Jifram fastened wooden pallets together to provide a base. These improvised pallets proved marginally satisfactory for several reasons. The pallets were not the correct size for the channel, thereby resulting in wasted space in the trucks. The pallets also splintered and broke down during the shipping process.

CBPP Solution:

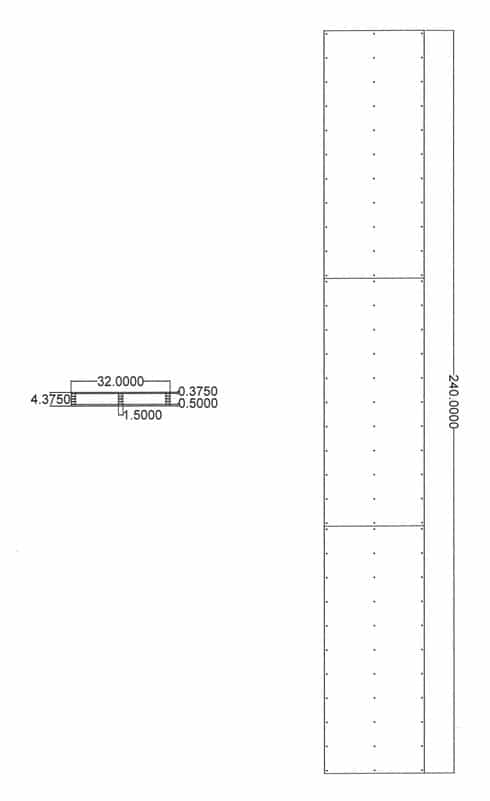

Jifram custom designed and built extruded plastic pallets sized to fit the Duct-O-Wire channels exactly. The pallets were fine-tuned and tested during multiple shipments to the customer.

Results:

These 23’ long custom built plastic pallets are proving to be a perfect solution for a closed loop system for Jifram and Duct-O-Wire. Shipping multiple trucks per week, it is projected that the custom built plastic pallets will be in service for at least two years without need for replacement. In addition, the integrity of the plastic pallets nearly eliminates damage during transit.